Applied Range

Mainly used in industries such as shipbuilding, vehicle manufacturing, steel structure engineering, pressure vessel manufacturing, and more. Suitable for welding various complex joints and thick plates with high efficiency. Capable of welding carbon steel, stainless steel, aluminum alloys, and other materials.

Equipment Characteristics

The equipment features advanced control systems and high-precision servo motors, ensuring stable and efficient welding. It supports multi-axis linkage and real-time monitoring, meeting the welding needs of large and complex workpieces with high quality and efficiency.

- Safety: Equipped with multiple safety protection devices.

- Efficiency: High welding speed and low energy consumption.

- Precision: High accuracy with minimal deformation.

Gantry dual drive galvanometer welding

Equipment Parameter

| Item | Specification |

|---|---|

| Laser Power | 1000W, 1500W, 2000W, 3000W |

| Wavelength | 1080±10nm |

| Modulation Frequency | 1-100Hz |

| Work Mode | QBH (Quick-Change) |

| Modulation | Adjustable |

| Operating Temperature | 10%-100% |

| Power Supply | Three-phase 380V |

| Cooling Method | Air-cooled |

| Operating Humidity | 170°-170° |

| Item | Specification |

|---|---|

| Welding Speed | 4000mm/min |

| Repeat Positioning Accuracy | ±0.5mm |

| Power Consumption | 10kW |

| Power Supply | Three-phase 380V |

| Total Weight | 1200kg |

| Dimensions | 3000×1500×2000mm |

| Control System | CNC |

| Operating System | Windows 10 |

AUTOMATIC WELDING (MULTI-AXIS PLATFORM LASER AUTOMATIC WELDING)

Applied Range

Widely used in industries such as aerospace, shipbuilding, automotive manufacturing, and steel structure engineering. Suitable for welding complex joints and thick plates with high precision and efficiency. Capable of welding materials like carbon steel, stainless steel, aluminum alloys, and titanium alloys.

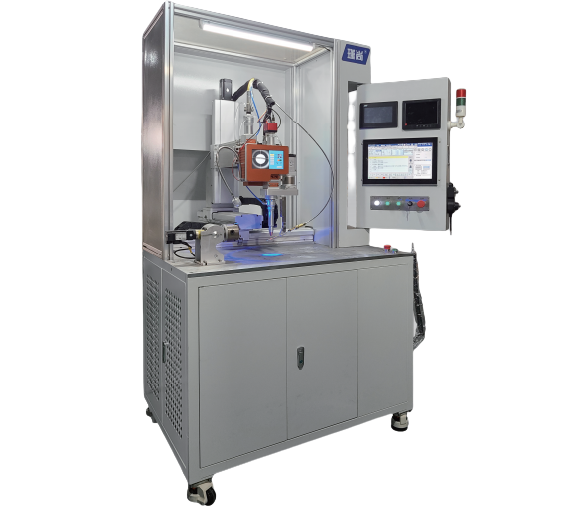

Equipment Characteristics

The equipment features a multi-axis platform with high-precision servo motors and real-time monitoring systems, ensuring stable and efficient welding. It supports complex welding trajectories and is adaptable to various workpieces.

- Precision: High accuracy with minimal deformation, suitable for intricate welding tasks.

- Efficiency: Fast welding speed and low energy consumption.

- Control: Advanced EtherCAT control system for precise and reliable operation.

- Flexibility: Modular design allows for easy integration and customization.

AUTOMATIC WELDING

Equipment Parameter

| Item | Specification |

|---|---|

| Laser Power | 1000W, 1500W, 2000W, 3000W |

| Wavelength | 1080±10nm |

| Modulation Frequency | 1-100Hz |

| Work Mode | QBH (Quick-Change) |

| Modulation | Adjustable |

| Operating Temperature | 10%-100% |

| Item | Specification |

|---|---|

| Welding Speed | Adjustable |

| Repeat Positioning Accuracy | ±0.5mm |

| Power Consumption | 10kW |

| Power Supply | Three-phase 380V |

| Total Weight | 1200kg |

| Dimensions | 3000×1500×2000mm |

Welding Head Parameter

- Welding Seam Width: 0.5-6mm

- Operating Range: Adjustable